At Accel Inc., we don’t wait for problems to happen before looking for solutions. We’re always asking: How can we do this better?

That’s exactly what happened when we took a fresh look at a long-running packaging program for one of our snack manufacturing clients. Nothing was “wrong.” Costs were stable. Operations were smooth. But we saw opportunities—little areas where fine-tuning processes could drive even greater efficiency.

So, we dug in. And when we sat down with the client for a meeting, we didn’t just review last year’s numbers. We surprised them with a 30% cost reduction we’d uncovered on our own.

Their response? “Wait… you did this without us asking?”

Yep. Because that’s just how we work.

Where We Found the Savings

Sometimes, the biggest efficiencies in supply chain cost reduction aren’t in massive process overhauls—they’re in the details. Here’s what we optimized:

- Refining Pallet Picks and Moves: We noticed that products were being handled more times than necessary, adding inefficiencies. A few small changes in workflow meant less movement, less labor time, and lower costs.

- Optimizing Recycling and Material Flow: Materials were being discarded in ways that weren’t as streamlined as they could be. By fine-tuning our recycling routes and how we handled WIP (Work-in-Progress) cases, we cut down on material waste and costs.

- Dialing in Production Rate Accuracy: By leveraging real-time production data instead of past bid estimates, we made more precise labor cost predictions, keeping budgets lean and efficient.

- Reducing Material Waste: Test-fit improvements and supplier adjustments led to savings in raw material costs—all without sacrificing quality.

The Results

- 37% reduction in direct labor costs

- 20% drop in indirect labor costs

- 14% savings in material costs

- 31% lower case price overall

All of this without changing the core process—just refining it.

The Takeaway for Your Supply Chain Cost Reduction Strategy

Here’s what most companies get wrong about supply chain cost management: they wait for costs to become a problem before addressing them. But by then, you’ve already left significant money on the table.

The hidden costs in your supply chain compound daily. A few extra material touches here, some inefficient workflows there, outdated cost assumptions everywhere—individually small, collectively massive.

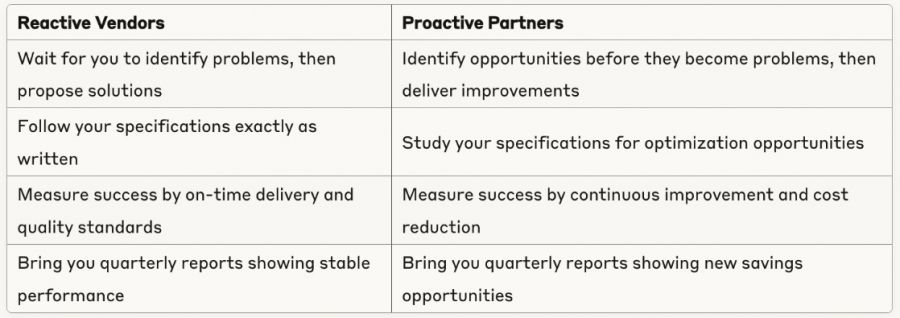

Most Vendors Execute: Great Partners Optimize

Think about your current supply chain relationships. Are your partners simply fulfilling orders and hitting deadlines? Or are they actively studying your processes, questioning assumptions, and bringing you solutions you didn’t know you needed?

There’s a fundamental difference between a vendor who says, “We’ll do exactly what you say,” and a partner who says, “We’ll do what you want, but here’s how we can make it 30% better.”

The partnership difference in supply chain cost management:

The Questions Every Supply Chain Leader Should Ask About Their Current Partnerships

- When did your partners last suggest a process improvement you hadn’t requested?

- Are your vendors studying your workflows for optimization opportunities?

- Who’s questioning your current processes to find better ways?

- Are your partners invested in your profitability, or just their contract compliance?

- How much money could be hiding in your “good enough” relationships?

True supply chain cost reduction requires partners who think like owners–partners who don’t just execute your processes, but continuously refine them. Partners who understand that your success directly impacts theirs and act accordingly.

The best supply chain partnerships aren’t transactional—they’re transformational. They turn routine operations into competitive advantages and hidden costs into discovered profits.

Ready to Transform Your Supply Chain Cost Management?

At Accel, we don’t wait for inefficiencies to cause pain before we act. We’re constantly evaluating, adjusting, and fine-tuning—because in supply chain management, proactive optimization beats reactive problem-solving every time.

We believe every process can be improved, every workflow can be refined, and every operation contains hidden opportunities for cost reduction. Because good isn’t good enough–we believe there’s always a way to make things better.

If you want a partner who actively looks for hidden costs in your supply chain—not just when you ask, but before you even know to ask—let’s talk about what opportunities might be hiding in your operation. Contact Accel today.