Three advantages Accel brings to the table to run agile market tests.

For food and beverage brands, picking the right co-packer is paramount. In your search for the perfect partner, packaging quality, workforce reliability, and cost effectiveness are standard—but critical—components to evaluate. But one additional quality you must not overlook is agility. Consumer behavior is changing rapidly, and you must be confident that your co-packer can quickly pivot to address what resonates with consumers.

The right co-packer can be a valuable strategic partner in helping you run nimble market tests and obtain actionable consumer feedback. Through our more than 25 years of experience working with leading food and beverage brands, Accel is positioned around three advantages that can help to increase your speed to market.

1. On-demand, highly certified staffing when you need to scale quickly

1. On-demand, highly certified staffing when you need to scale quickly

Does your co-packer have the capacity to handle an uptick in production volume? If staffing or capacity shortages arise, you need to be confident that your co-packer will have the resources and experience to keep production lines running—even test programs that are in pilot stage.

We provide our clients with reliable performance by implementing and adhering to strong compliance programs for quality, production, and maintenance. Accel is registered with the FDA and holds certifications in SQF 8.0 (GFSI), ISO 9001: 2015, GOTS (for organic and natural product), and more. We’re a woman-owned business certified by the Women’s Business Enterprise National Council (WBENC), utilize GMP, and operate with a Lean Six Sigma culture. To decrease employee turnover and thus increase performance reliability, we invest in our workforce with strong training programs and opportunities for promotion.

What sets us apart is that we own our own staffing company, creating even more workforce reliability for our clients. This one-of-a-kind solution helps to ensure we can scale staffing to increase packaging volume and speed when you need it. This includes adding second and third shifts when necessary, as well as preventing labor shortages when an issue arises. Through our flexible staffing model, which includes our core production staff and on-demand, year-round temporary staff, we offer faster speed to market without compromising quality or cost.

Scaleable workforce pushes products to market faster

With our trained and qualified staff in place, we recently designed an innovative solution for our client, a leading Fortune 500 company.

Our client challenged us to run multiple product SKUs on the same line with variations in product formulation, with the goal of getting their products to market faster than before. Our team of engineers took on this challenge by reconfiguring the production line to run multiple SKUs and packaging configurations simultaneously. We ensured quality was maintained for batch and lot control through line configuration, technology installation, and quality control measures.

The newly reconfigured line now produces two different products with four package configurations each on just one line. From the time we received the request, we delivered in just 10 days, passing approvals from our client’s engineers and quality control staff. The best part is that, to the surprise and delight of our client, the line reconfiguration led to additional efficiencies that reduced the overall cost of production.

2. Turn-key capabilities in one location

Partnering with a co-packer with full packaging capabilities allows you to manage your entire production line in one location, creating greater efficiency and speed across the development process. More importantly, a co-packer with a connected supply chain is able to more nimbly scale production volume, enabling you to operate small pilot plants and large-scale programs simultaneously—without driving up cost. This allows you to get your product to market faster and adapt to consumer feedback in near real time.

After working with food and beverage companies for more than 25 years, Accel has built an integrated supply chain designed to offer our clients turn-key packaging capabilities. Anchored by our 517K square foot facility, which is equipped with more than 60 packing lines and 35 shipping doors, Accel’s production campus shares its home with more than 20 trusted companies, all within a five-mile radius. The companies of our campus are long-standing partners who can help provide solutions across the full packaging process, including bottling, filling, formulating, and packaging. By leveraging our turn-key solutions, we can provide our clients with improved turnaround times while maintaining low costs, allowing you to run small programs when you need to test product adoption on the market.

Connected supply chain massively cuts costs

We recently put our turn-key capabilities to use to consolidate our client’s supply chain onto our campus, which is strategically located in the heart of the Midwest—Columbus, Ohio. Doing this gave our client access to nearly 50 percent of the U.S. population within a 10 hour drive or 1 hour flight, which drastically reduced their transportation mileage from 300K to 36K per year, saving them more than $1.8MM in annual shipping costs while improving speed to market and reducing their carbon footprint.

3. Innovative technology that helps you stand out

A forward-thinking co-packer ensures you not only see immediate improvement in speed and efficiency, but also long-term value through cost savings and sustainability. During your search to find your co-packing partner, you should inquire how the business is continually innovating and ask to see tangible examples.

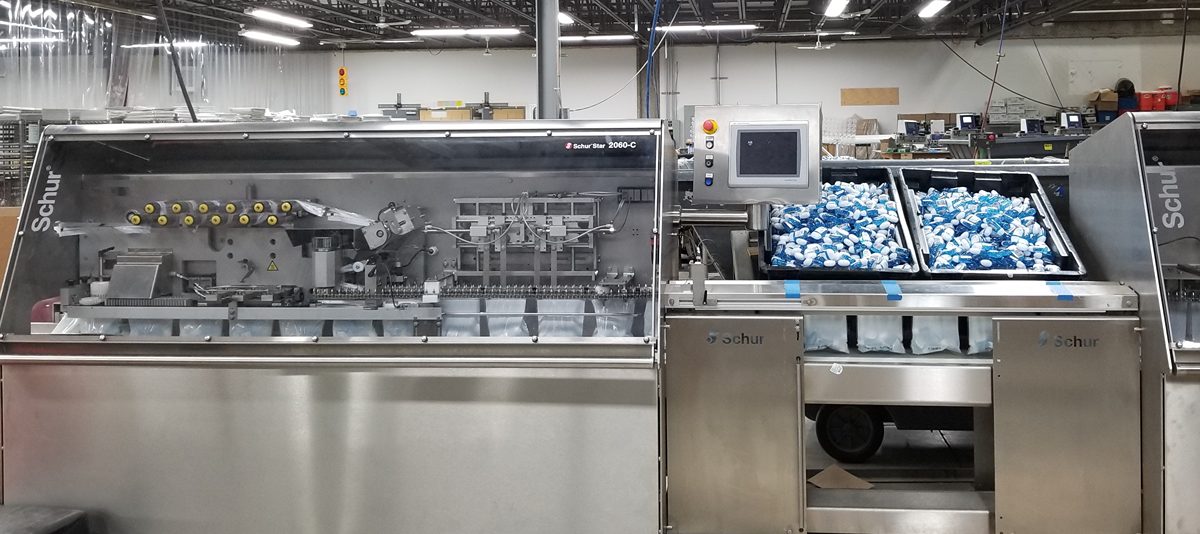

At Accel, our innovation is driven by our investment in automation and sustainability. One of our flagship pieces of innovation is our Schur®Star System pouching machine. Capable of running a wide variety of packaging sizes and materials, our machine runs up to 80 bags per minute, increasing Accel’s overall productivity and capacity. Because it brings improved efficiency to our production line, the Schur machine creates a flexible and cost effective way to perform both nimble market tests and product promotions quickly and efficiently.

Visually compelling labels are no longer enough to grab the attention of consumers. And that’s where the Schur®Star System really shines. It’s able to produce unique packaging shapes and sizes in pouch and gusseted form, empowering our clients to design and launch out-of-the-box product packages to help them stand out on increasingly crowded shelves. Through our innovative approach to packaging, Accel partners with our clients to help them bring more durable, sustainable, and unique products to market.

Bringing agility and innovation to your business

The search for a perfect co-packing partner is a critical process that shouldn’t be taken lightly. Throughout our 25+ years as a co-packer, not only do we understand the importance of this process, but we’ve had the experience of going through it with some of our clients who are leaders in the packaged food and beverages, beauty, and wellness industries.

Our valuable insights and years of experience driving innovative agility as a packaging solutions provider will help you accelerate speed to market and testing, improve customer feedback collection, and adapt rapidly to be in the position to win bigger. If you’re interested in how Accel can help you perform nimble market tests, contact Chairwoman Tara Abraham to learn more.